Flexbar 300-AE automatic rebar shearline

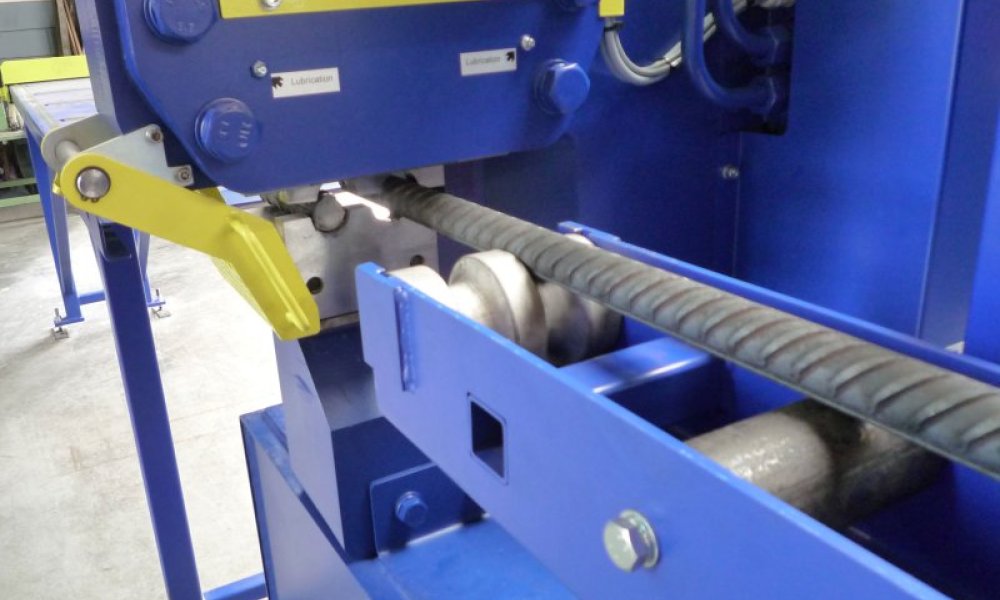

Rebar shearline with automated length stop and one-sided automatic ejecting, processing of bars from Ø8mm up to Ø50mm

- Active storage rack for rebar with 1 or up to 6 levels

- Electrically driven entry conveyor with coated rollers

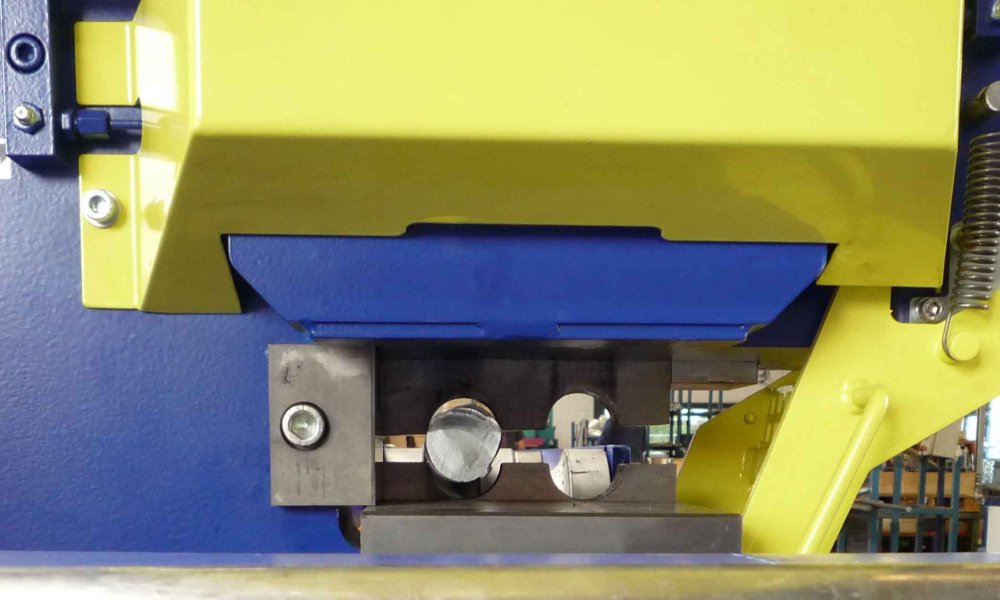

- Hydraulic rebar cutting machine with 300mm blade width

- Automatic length stop for precise length adjustment

- PLC control with touch panel, possibility to set up to 5 different cutting lengths in one cycle

- Automatic ejection after cut, at pre-selected position, for maximum utilization of collection boxes

- Possibility to integrate bending table/rebar double bender

- Easy operation, low maintenance

- Capacity approx. 10 - 25 tons per shift