Multibar 300/500 automatic shearline

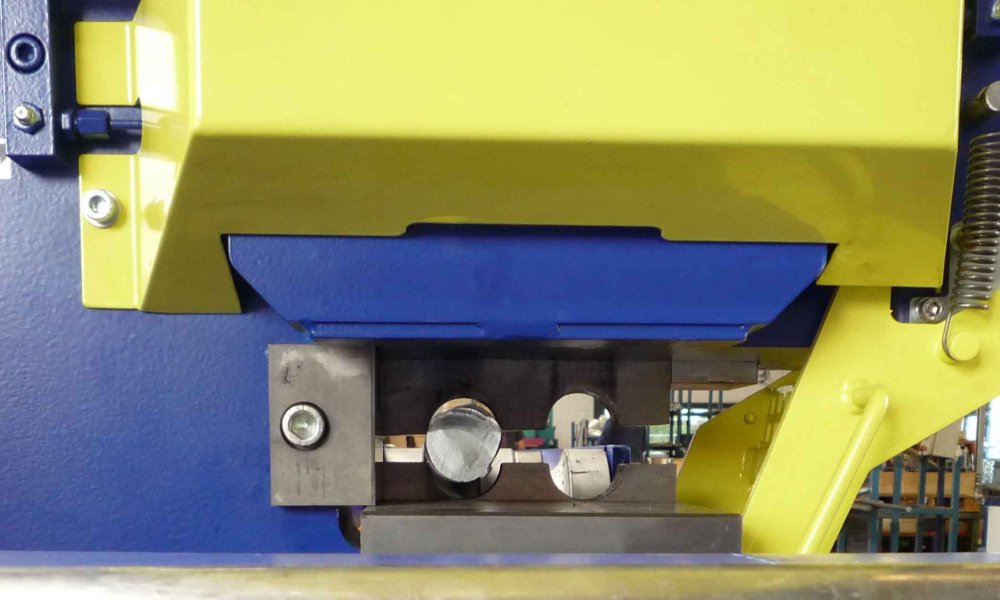

Rebar shearline, with high cutting capacity, for bars from Ø8mm to Ø50mm

- Available with roller conveyors and cutting machine in 300 mm or 500 mm width

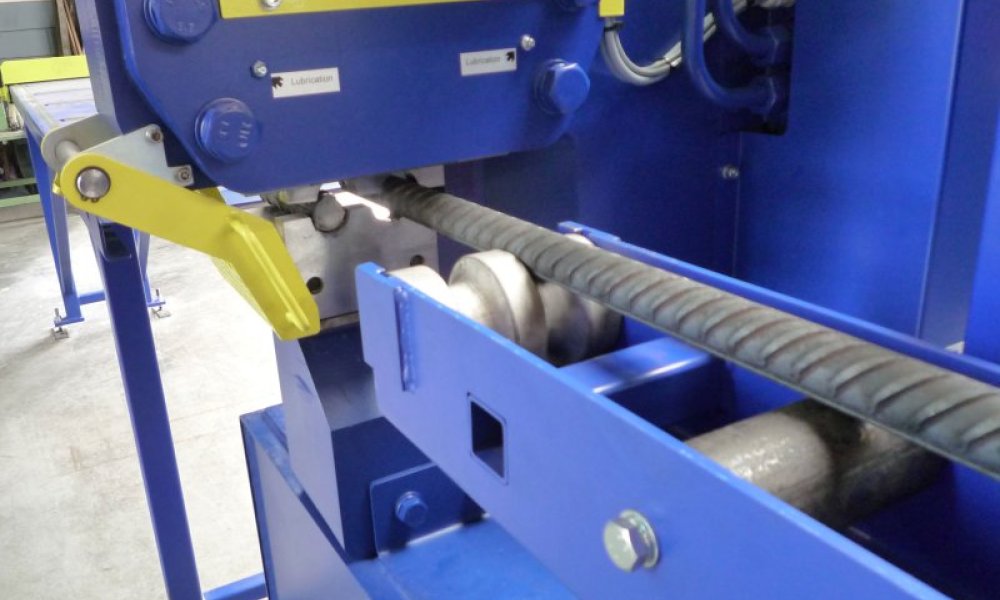

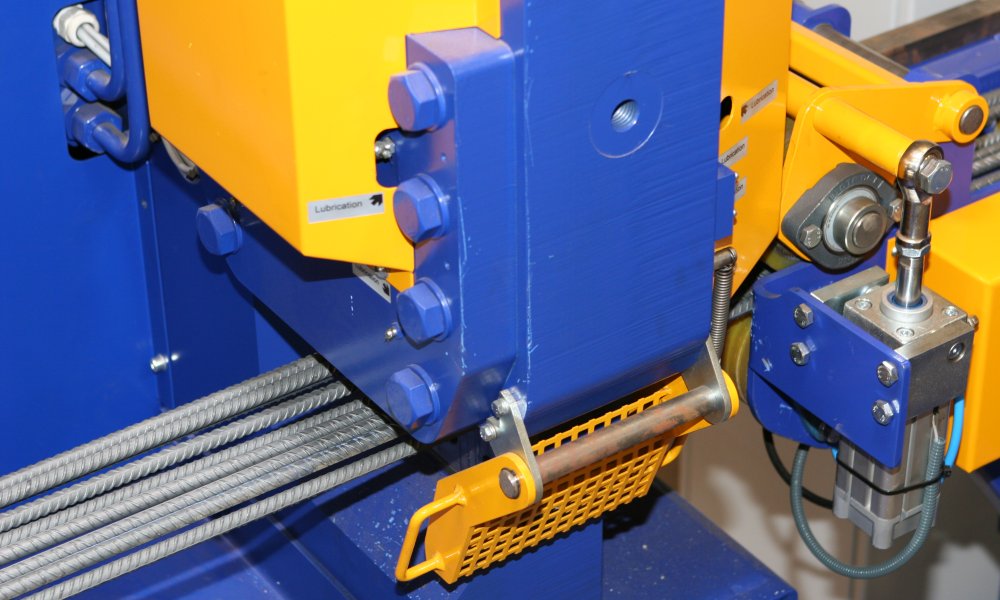

- High cutting performance even with smaller diameters due to high roller conveyor speed and high cutting speed

- Dimensioning with fixed measuring stops every 500 mm and mobile cutting machine for quick and dimensionally stable cutting of small and large series

- Optimum utilization of the internal storage pockets on both sides next to the measuring table through automatic positioning and ejection of the cut material

- Intelligent PLC control with touch panel, easy-to-use user interface, cutting optimization, online support, network connection or barcode scanner

- Unsurpassed build quality and robustness, minimal maintenance and low downtime

- Modular structure, adaptable to customer needs

- Possible integration of a double bending line